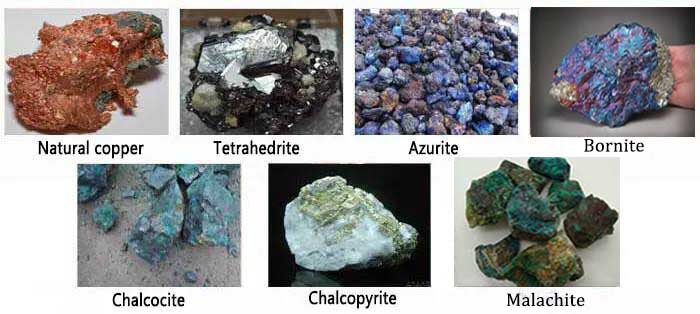

Copper ores mainly include natural copper, sulfide ore, and oxide ore.

Among them, copper industrial minerals include: natural copper, chalcopyrite, chalcocite, chernozemite, azurite, malachite, etc.

Building cost-efficetive copper processing plant machine and process method

Main process method: flotation copper processing plant with high recovery rate, large processing capacity and low cost.

Main equipment: jaw crusher, ball mill, spiral classifier, flotation machine, shaking table, jig machine, etc.

Main process of copper ore processing

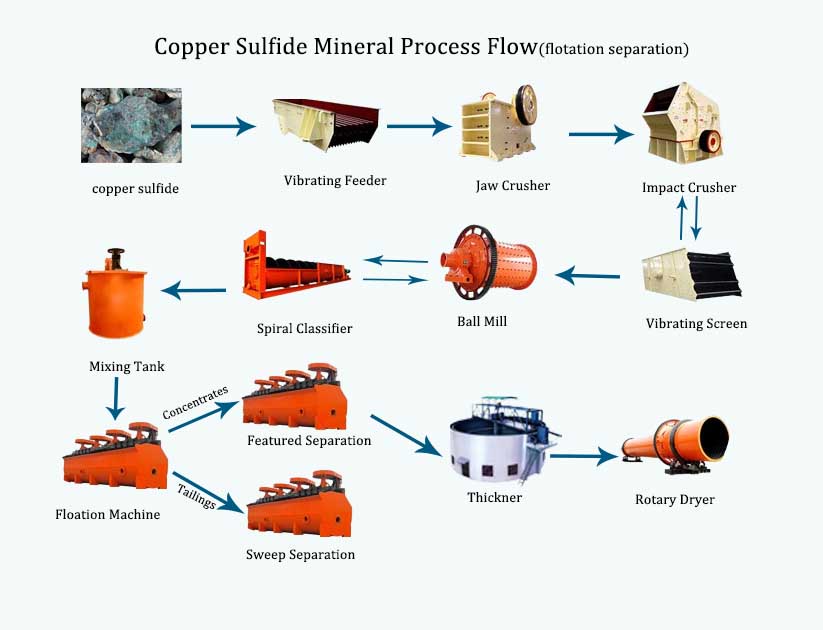

✱ Flotation copper ore process

The most popular and cost effective (copper sulfide) copper processing plant method is flotation to get high grade copper concentrater with high recovery and copper enrichment.

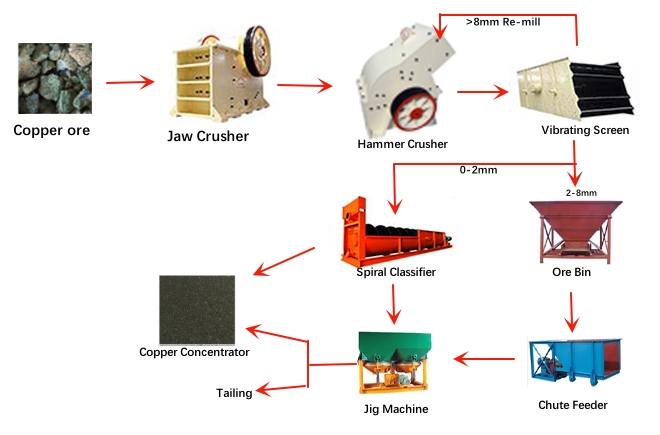

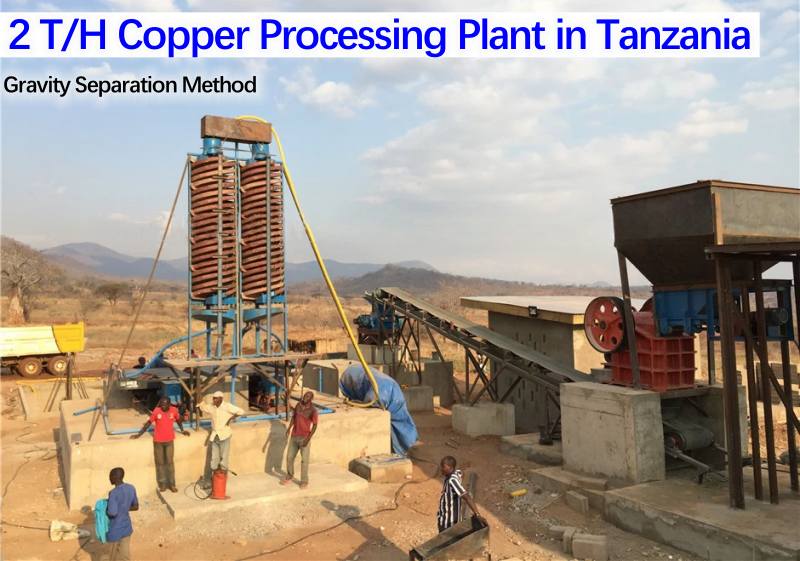

✱ Gravity separation of copper ore process

Coarse copper ores are commonly used for gravity separation process. Such as copper oxide.

Copper gravity sepration plant with cost saving and high efficiency.

✱ Copper Leaching Process

Crushing → Agglomeration (if heap leaching) → Leaching (Tank/Heap) → Solution Extraction → Solvent Extraction → Electrowinning → Final Copper Cathodes.

Copper ore leaching plant equipment for sale.

Jaw crusher, cone crusher, vibrating screen, leaching tanks, thickeners, centrifuges, filter presses, etc.

Zoomjo with 30 years of experience in copper ore processing plant equipment and provide one-stop service, design, installation, commissioning, technical training, lifelong after-sales service, etc.

Contact us to get more professional copper ore processing plant solutions and equipment costs.