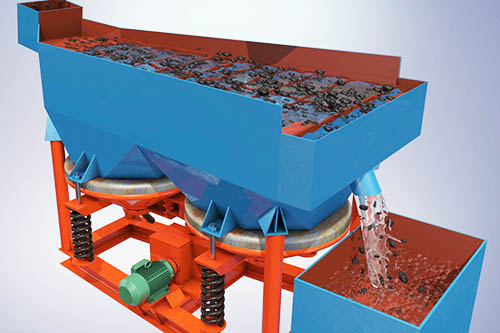

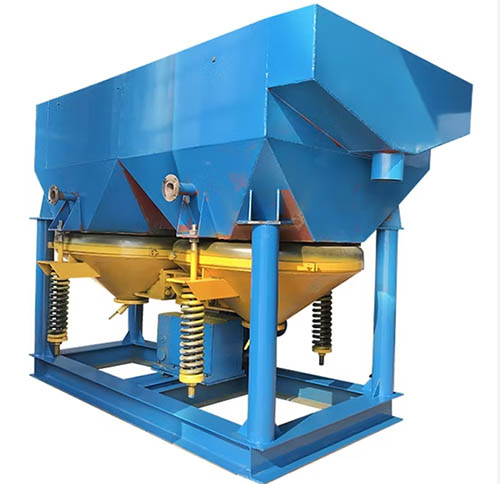

Jig seperator machine (jig concentrator) is a highly efficient, economical and durable gravity separation mineral processing equipment. It separates minerals of different particle sizes based on density differences that is widely application in allucial gold, placer gold, coal, iron ore, tungsten ore, tin, diamond, lead-zinc ore, chrome, antimony, etc.

Jig Concentrator Advantages:

Wide range of applicable particle sizes: Effectively separates materials from coarse particles (10–50 mm) to fine particles (0.1 mm)

High throughput and recovery rate: Processing capacity increased by 40% compared to traditional jigs, with recovery rates reaching 80%–95%

Energy-efficient and Eco-friendly: Primarily uses water as the medium, eliminating the need for chemical agents

Low investment cost: Simple structure, easy to install, operate and maintain

In the beneficiation of rock gold and placer gold, jig machine is commonly used as roughing or scavenging equipment, not only significantly enhancing gold recovery rates but also reducing production costs.

Secondly, we also have diaphragm jigs, hydraulic cyclone jigs, air pulsation jigs (sawtooth wave jigs also belong to this category), etc. We can customize or choose a more suitable equipment type according to the customer's ore type and needs.

The working principle of a jigger may seem complicated, but it is actually very simple. Simply put, a jigger uses the difference in specific gravity of minerals to perform sorting. When the minerals enter the jigging chamber, the water flows upwards to impact the minerals. Due to the different specific gravity of the minerals, they react differently. The heavier minerals will sink, while the lighter minerals will float to the lower layers. This is the sorting process of the jigger.