Chrome gravity separation process is one of the most widely used chrome wash plant chrome spiral plant nowadays, which can effectively separate chromite and chalcopyrite minerals and obtain high grade chrome concentrate.

Since most of the chrome ore is weaker magnetic, so we often customise the gravity separation process for our customers.

The process is simple in operation, large in capacity, low investment cost, high sorting efficiency and high chrome ore enrichment.

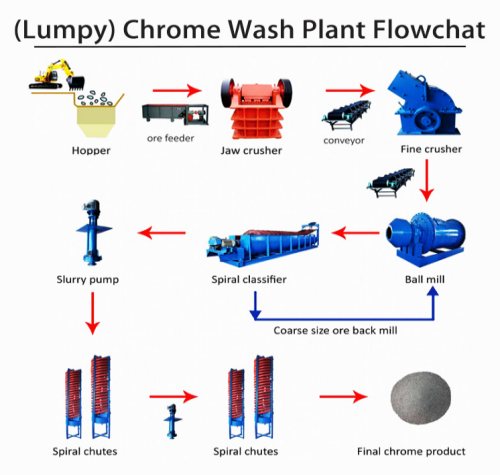

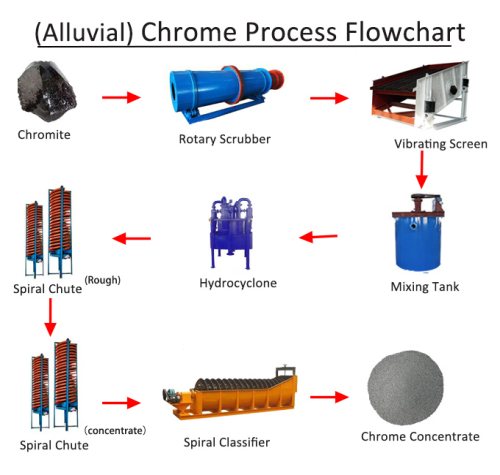

1. Crushing: The raw ore is first crushed by jaw crusher or cone crusher, which makes the particle size of crushed material ≤ 20mm.

2. Grinding: Before entering the ball mill first through the jigger, for the first time to select, and then through the ball mill for grinding, grinding particle size ≤ 2mm

3. Gravity Separation: The ground material first passes through the spiral chute for roughing, and then refined by shaking table.

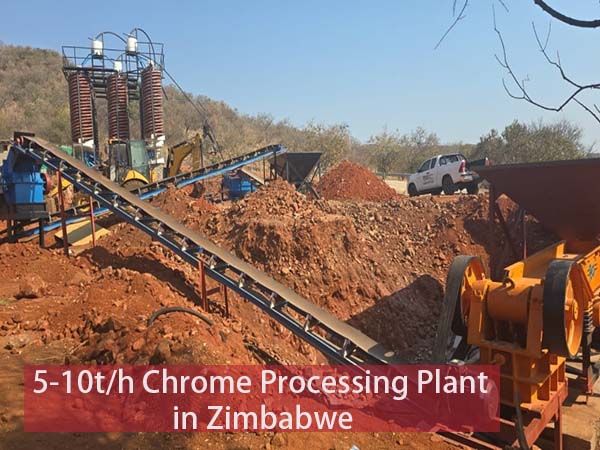

Different beneficiation processing solutions are equipped with different equipment, we can customize the suitable chrome ore washing plant solution and chrome ore processing equipment for you based on the raw ore analysis lab report.

If you are planning to build chrome washing plant chrome ore processing plant, please tell us your detailed requirements and we will offer you free solution and estimated prices within 24 hours!