Fluorite is a kind of low hardness, brittle ore, very bright color, can be used in the production of hydrofluoric acid, cryolite, etc. When fluorite is added, it has super high application value in chemical, glass, construction, cement and other fields.

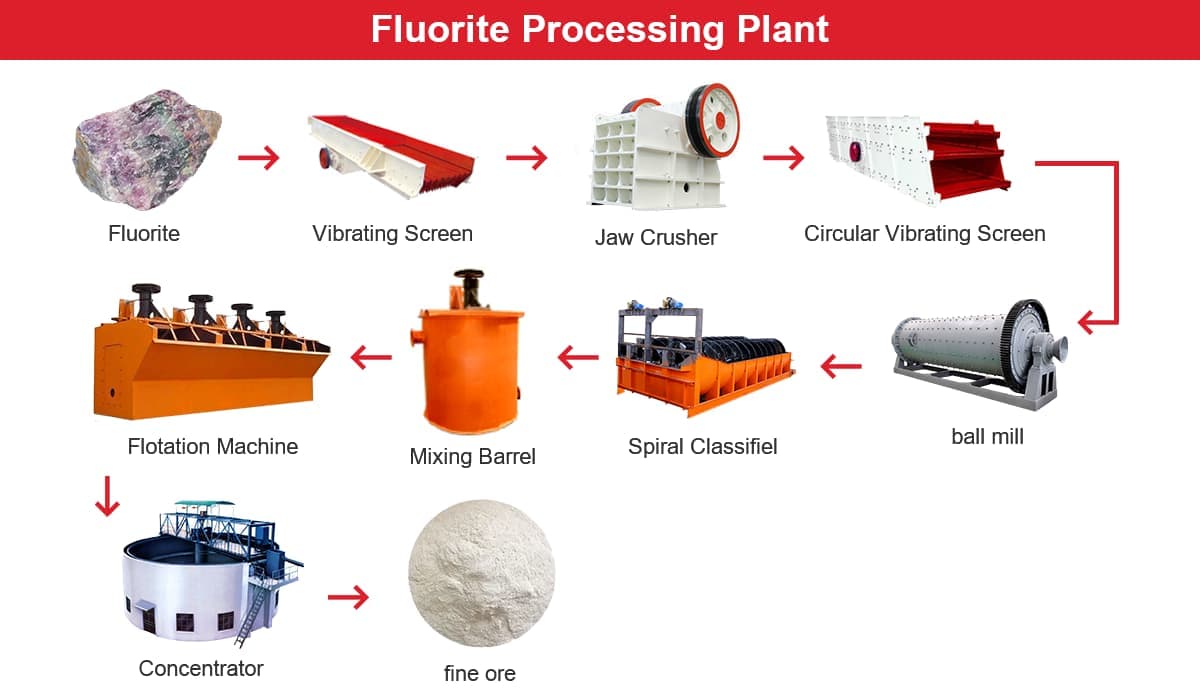

The fluorite is evenly fed into the vibrating feeder, which evenly feeds the iron ore into the jaw crusher, which crushes the fluorite in the first stage, and then sends the crushed fluorite to the cone crusher for the second stage crushing through the conveyor, after which the crushed fluorite is screened by the circular vibrating screen, and the unqualified fluorite is returned to the cone crusher for crushing, and the qualified finished product is first screened by the circular vibrating screen in the second stage. The qualified finished product is firstly screened by circular vibrating screen and then transported to the finished product area by belt conveyor. Then the fluorite will be processed by rotary kiln, ball mill, shaking bed and other equipment, that is, the finished product.

1, the production line will be reasonable fluorite hardness treatment, so that the output fluorite high quality, and the whole production line is running smoothly.

2, fluorite ore beneficiation production line configuration of wearing parts using the current domestic strong wear-resistant materials, long service life, bringing considerable economic benefits.

3, fluorite ore dressing production line has the advantages of high production, low energy, high processing capacity, economic and reasonable, etc.