Customer Background

The customer has been considering whether to set up a gold processing plant or not, and has been communicating with our sale manager and engineers for more than a month, and finally decided to adopt our customised solution to set up a gold processing plant.

Customer pain points

1, Issues of capital for plant construction

2, Stability and durability of equipment

3, Issues of future earnings

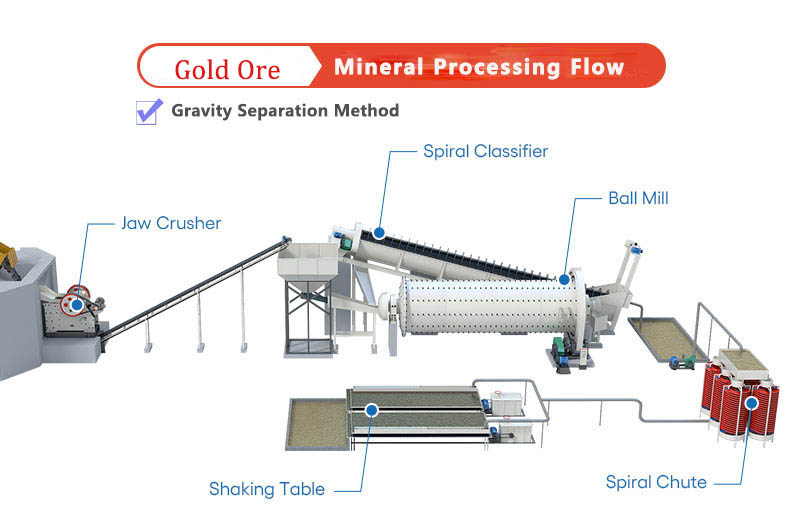

15TPH Rock Gold Processing Plant Solution

Details of the gold processing plant

Crushing Process: Jaw crusher & hammer crusher

Raw ore is fed into the Jaw Crusher through the vibrating feeder. 0-1000mm ore is roughly crushed by the Jaw Crusher, with discharge size of 10-200mm, and then finely crushed by the hammer crusher, which grinds the crushed stone to less than 20mm.

Grinding Process: ball mill and spiral classifier

The feed size of the ball mill is 200mm. Unqualified crushed stones will be returned to the jaw crusher or hammer crusher through the conveyor belt, and the crushed stones that meet the specifications will be sent to the ball mill through the conveyor belt. The ball mill grinds the ore into powder, and the output size can reach -0.3mm.

The ore pulp gold after grinding is classified by spiral classifier to separate the coarse and fine particles in the ore pulp. The coarse particles gold will continue to return to the ball mill for further grinding.

Gravity separation process: spiral chute and shaking table

The fine particles gold will be sent to the spiral chute for roughing through the slurry pump to improve the recovery of gold, and then it will be selected through the shaking table and finally concentrated into gold concentrate.

Customer feedback

The factory has been running stably for 18 months. We are very lucky to have chosen zoomjo mining equipment manufacturer. The design plan is very suitable for the site planned by our factory and provides us with EPC+ MO one-stop service, which not only saves investment costs but also increases production capacity. The high-grade gold ore and the increase in recovery rate directly make us profitable within 2 years.